Feeding Soay Sheep in Winter: A Sampler of Practical Solutions

For those of us lucky enough to have grass pastures in summer, feeding hay twice a day through the winter in the cold and rain is an annual reminder that not everything related to sheep-raising is fun. In plain fact, it’s a nuisance having the animals’ dietary needs dictate our daily schedule. How to keep the hay dry. What to do about the accumulated muck from all those little feet trampling the same spot twice a day. How to get the hay into either a feeder or a rumen, and not on the ground. All of this is daunting at first. The good news? Enterprising metalsmiths, carpenters, and Soay breeders have devised a goodly number of economically rational solutions to the winter feeding dilemma.

Before I launch into the sampler of feeders, I’ll share with you a few factors you might want to keep in mind when considering what will work best for your setup. Not surprisingly, there are tradeoffs.

Purchase or build. Cost is a threshold factor, of course (assuming you can make a feeder for less than you’ll pay a commercial source), but for many shepherds, time and access to a supplier also enter the equation. Plus, homemade feeders can be customized in ways that off-the-shelf products cannot.

Cover or don’t cover. If you feed your animals in a barn or other building with a roof, skip this one. If you feed outside, read on. Chief among the advantages of covered feeders is the assurance the hay will stay dry until the animals eat it. Also, your gluttons – the big ewes who always shove their way to the front of the cafeteria line – will not be able to stand up and pull great tufts of hay out and spill it on the ground. Our Soay have no table manners and I refuse to install a TV in their pasture so Martha Stewart can give them lessons. Here is our “rainbow” breeding group – mahogany, tan, and black — at their small feeder.

The big girls chomping away are Portia on the left and polled Allspice on the right. They should be grateful they drew stud muffin Fenugreek (the tan fellow in the middle) as their playmate this year and mind their manners. Not a chance.

The only real downside to covers is they tempt a shepherd to fill a large feeder and then not show up in the field again for two or more days, during which time the sheep will pick through the hay for the goodies and leave all the less attractive stems in the bottom of the feeder. Despite their legendary stupidity, sheep figure out quickly whether or not they need to be members of the Clean Plate Club and if they get accustomed to cherry-picking, they will waste a lot of pricey hay.

Sizing the slats or grid. The typical commercial feeder has either vertical slats 4 inches apart or 4-inch mesh fence, too large for Soay. Although adult rams and ewes probably would do okay with them, a 6-to-8 month old lamb can poke his head through a 4-inch opening in search of hay, get caught, panic, and hurt or kill itself. Feeders sized for Soay with rigid (steel or wood) feeding slats or mesh must have openings of less than 3 inches. Another solution is to use flexible pipe such as PVC in vertical slats, which solves the problem of a lamb getting stuck because the pipe will “give” enough to let the lamb’s head work its way back out, but it probably also means replacing pipe more often than if the slats are made of steel or wood.

Wood vs. metal feeders. The tradeoffs here are weight and ease of handling, durability in the weather, cost, and the ability to withstand the occasional battering ram.

The Sampler. Since this is my blog, I get to talk about our feeders first. Of necessity (the barn is full of hay), our Soay live in the fields day and night, with 12 x 8 roofed shelters in each pasture area. Here are the older, non-breeding ewes taking shelter from a recent rain. The contraption in the background that looks like a carnival wagon is a dandy sheep trailer made locally eons ago.

This style and size of shelter is good for protecting our animals from winter rains and the highest-sun days of summer, but is not designed for, or big enough, to include feeders. For feeding, we need stand-alone equipment. Portability also matters because we re-group and move at least part of our ewe flock twice each winter, first in December once breeding is over, and then again in early March when the pregnant ewes migrate to the Maternity Ward for lambing. Once we figured out how long it would take to build the number of feeders we needed, we decided to purchase ours from Bill and Susan Shaul in California. Here’s what our biggest Shaul feeders look like in the pasture area we use to winter-feed all our ewes before lambing.

Shaul’s and other commercial feeders of this style do a good job of protecting the hay from tumbling onto the ground. Our smallest weaned lambs will feed quite adequately from the hay that falls into the trough below. The next picture shows a mixed group of ram lambs and adults chowing down in the Bull Pen. As you can see, the little guys are not shy about bellying up to the bar.

In all candor, we did have one enterprising lamb crawl into a feeder recently and somehow she got stuck below the slatted section, a first for us. Thankfully, Steve was able to extract her without harm, thank goodness. The shorter Shaul feeders like the one pictured above can be comfortably carried by two people or by one person with a pair of Shaul’s wheels, like a hand truck only the wheels fit into the end legs of any of their feeders. The really long ones need to be moved using the tractor and forks.

In lieu of covers, Steve is in the process of making ramada-like structures of 4×4 pressure-treated wood posts and corrugated metal placed astride each set of winter feeders. When we bought our feeders, we elected not to get covered ones, and not just for economic reasons. Oregon is so mild compared to Chicago that until we had been through a full winter, we simply failed to appreciate the impact on our sheep and our pocketbooks of feeding them consistently wet hay. Plus, we thought the extra step of opening and closing lids sounded like a hassle. I don’t really know whether we would get covered feeders if we were starting from scratch now. But it has worked out well for us anyway because the existing shelters in our winter pasture areas won’t hold all our animals now that our flock has grown so much. The stand-alone covers Steve is making will provide additional space for the sheep to come in out of the rain.

If they were large enough, our new stand-alone covers also could solve the problem of the persistent deep muck that builds up over the winter where the sheep feed. For this problem, we decided to keep the covers a smaller size and instead to concentrate on the ground itself. Look back at the picture of our long feeders. See that nice raised area surrounding them? It is the pasture equivalent of rubber shower mats. Our trusty summer ranch hand, Shawn (“Red”) Olsen, built us a perimeter of railroad ties set slightly into the surface of the pasture for stability, then filled with crushed rock. I am happy to report that after a full rainy season of experience, these “balconies” mean no longer do either the sheep or the shepherds slip in muck at the feeders.

And there’s a nice side benefit. Remember hoof trimming? We’ve observed a significant decline in the rate of new hoof growth in our Soay who have to walk across rock twice a day to eat.

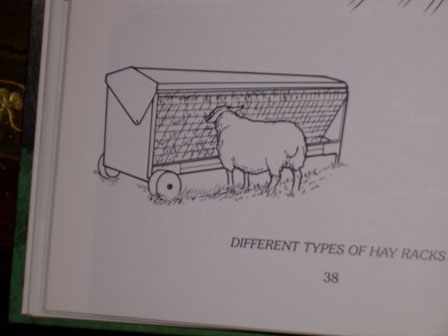

On to covered feeders. The next set of pictures shows the feeder in my friend Anne’s field in Knayton, near Thirsk in Yorkshire, England. Remember Anne? She’s the total stranger I heard from out of the blue almost a year ago when I was starting this blog. Anyway, since last we encountered Anne on these pages, she has acquired a new adjacent pasture, lucky her, and from the looks of her sheep feeder, it should roll next door to the new pasture quite easily if need be. The first picture is the design itself.

And now the feeder itself. Look at these wheels. I’ll have to ask Anne if they are big enough to allow her to move the feeder by herself when it is empty.

In some respects, Anne’s feeder is just a Shaul of a different color, same open sides for feeding, same trough to catch the scraps of hay. But look at that wonderful roof, hinged on the ends so Anne can simply tip it back on its hinges (marked with an arrow) when she is ready to fill the feeder.

Reminds me of the red and white coolers, Igloos, I think is the brand name, that have the same sort of balanced, roll-back top. Anne’s hay certainly does not get fouled by rain, does it?

The mesh in Anne’s feeder is 2.5″, small enough to keep her lambs safe, and don’t they look contented facing the camera here.

Although the transportation costs probably eliminate Anne’s supplier for most readers of this blog, in the interests of completion, here is what she has to say about her source: “They are purchased from our local agricultural supplier. I guess they are made by a local small-time workshop by the look of them. All in this area are the same – we all use the same supplier (“Sam Turner”).”

Now it is true confessions time: I have hay feeder envy, big time. A couple of weeks ago our friend Kate Montgomery of Blue Mountain Soay, from whom we purchased a major part of our foundation flock, sent me pictures of her brand-spanking-new hay feeders, and are they ever the cat’s meow. Look at them, first unpainted and lined up in a row,

and then with their first coat of not-John-Deere green paint.

Kate and Bob made these feeders, hinged roofs and all, just before a major, 100+ MPH windstorm struck their farm. When I asked Kate for a sketch, here’s how she described their work: “It’s a way-easy thing if you build them in assembly line status. We used good plywood and 2x4s. 2 people can “rickshaw” them around. The sheep love them. Otley has to wait her turn but others are right in there. For tiny sheep you need to make the ‘shelf’ more narrow.”

What versatile feeders these Blue Mountain Beauties are, big enough to feed a good number of Soay but small enough to pick up and move. Kate and Bob chose to use flexible pipe for their vertical slats.

We’ll be eager to hear how this material works out. Meantime, I’m seriously considering putting a couple of these feeders on my Santa wish list.

So much for the brief tour through Soay feeders. In the course of putting this post together, I came across several helpful websites and I only scratched the surface. For example, the MidWest Plan Service run by Iowa State University in Ames bills itself as providing “practical, expert agricultural information for 76 years” and we cannot say enough good things about these folks. The design of our shelters, for example, evolved from a MWPS plan. In response to an inquiry about feeders for “miniature” sheep, Kathy at MWPS sent me to www.ag.ndsu.nodak.edu/abeng/sheepplans.htm, which also looks promising for purchased creep feeders, especially for newly-weaned lambs until they can belly up to the bigger feeders. And so on and so on. If you have another feeder style that works well for Soay, I hope you will share it with readers of this blog, either by commenting directly or sending me a private e-mail and I’ll do an update to this post.

Best wishes to everyone reading this post for a bountiful Thanksgiving feast with your friends and family. May your animals’ dinner stay dry and your dressing and turkey stay moist, and let us all give thanks for our good fortune in finding and raising these appealing little creatures.

For now …